- Home

-

Products

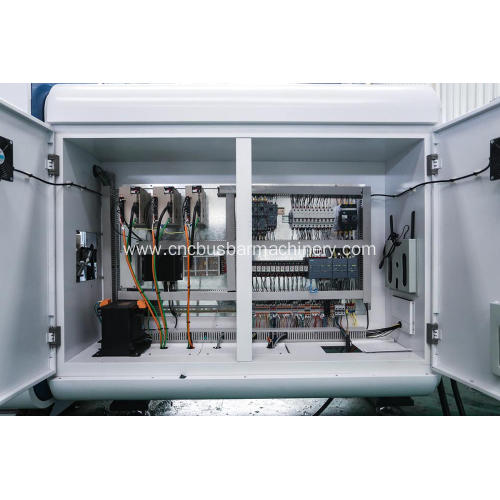

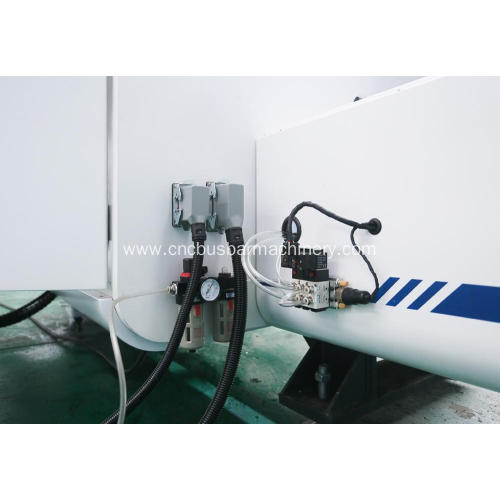

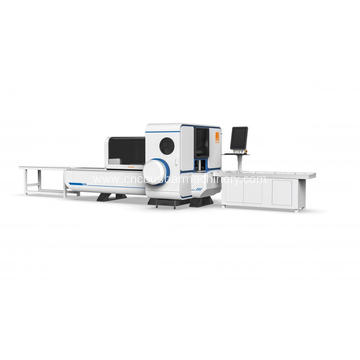

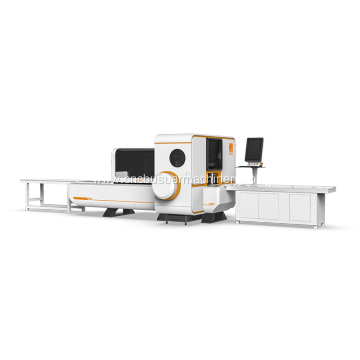

- Intelligent Busbar Machine

- Automatic Winding Machine

- HV Coil Winding Machine

- Cut To Length Line Machine

- Shearing Steel Strip Machine

- Polyurethane Foam Sealing Machine

- Silicone Foaming Machine

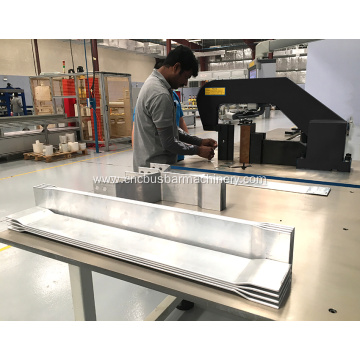

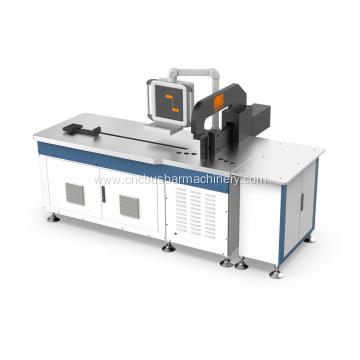

- Busbar Machine

- Busbar Bending Machine

- Busbar Punching Machine

- Busbar Processing Machine

- Foil Winding Machine

- Hydraulic Busbar Cutting Punching Bending Machine

- Vertical Winding Machine

- Busbar Cutting Machine

- Notching Machine

- About Us

- News

- Video

- Contact

- Send Inquiry

- 360° Virtual