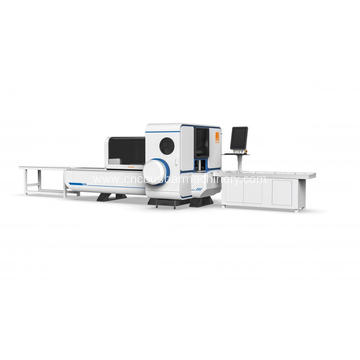

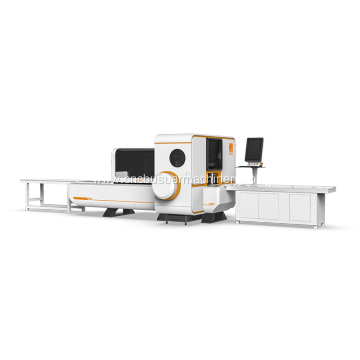

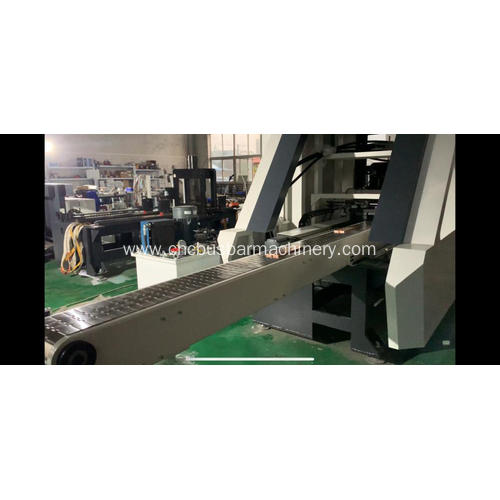

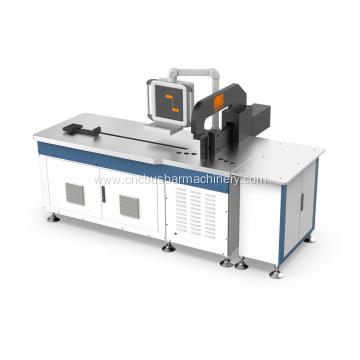

Model No.: EMAC-BP

Brand: Euro-Asia/Gaoji

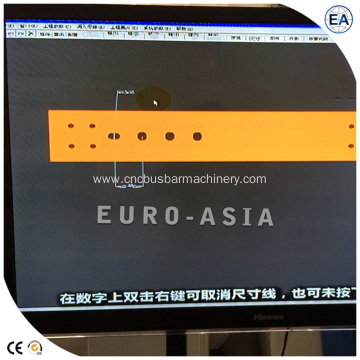

Whether CNC machine tool: Cnc

status: New

Machine type: Hydraulic Press

Nominal force (kN): 4000

power: Hydraulic

place of origin: China

Core selling point: Automatic

warranty period: 1 Year

Applicable industry: Manufacturing Plant

Where to provide local services (in which countries are there overseas service outlets): None

Showroom location (in which countries are there sample rooms overseas): None

Marketing type: New Product 2020

Mechanical test report: Provided

Video factory inspection: Provided

Core component warranty period: 1 Year

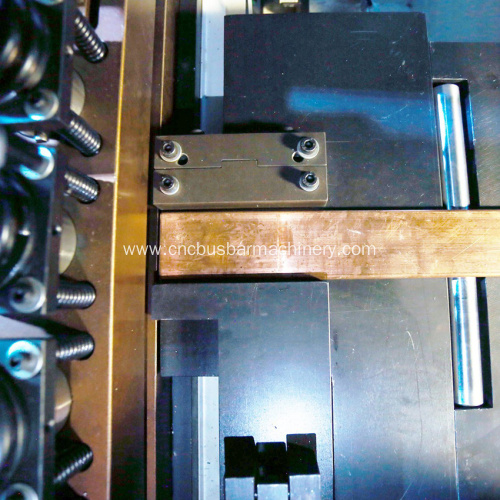

Core components: Pump, Gear, Motor, Plc

Condition: New

Type: High-Speed Punching Machine

Punch Shape: Semi-Open Punch

Slider Movement: Double Action

Slider Drive Mechanism: Screw Press

Controlling Mode: Cnc

Automatic Grade: Automatic

Power Source: Hydraulic Pressure

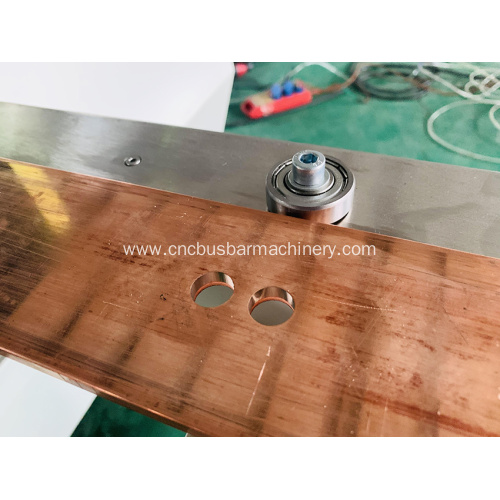

Precision: High Precision

Certification: Iso 9001

Precision Ball Screen: Taiwan Hiwin