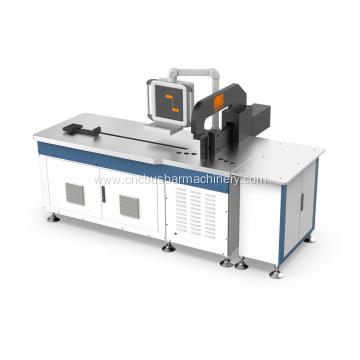

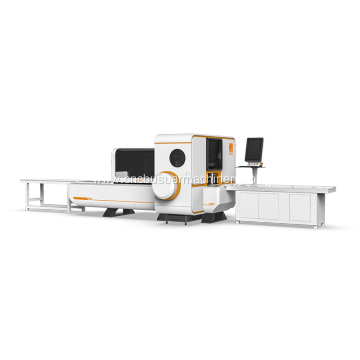

Model No.: EMAC-BB

Brand: EA

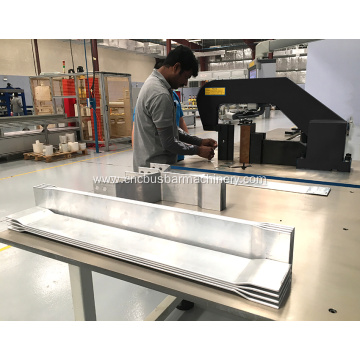

Machinable material: Alloy, Brass / Copper, Aluminum

Old and new: New

place of origin: China

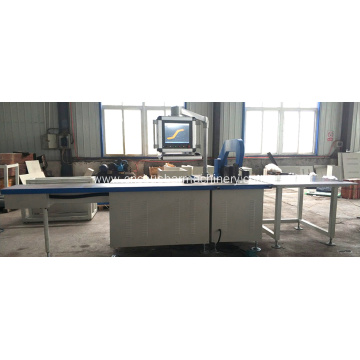

degree of automation: Automatic

Additional features: Swaging

Certification: Ce, Ce

warranty period: 1 Year

Out-of-warranty service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

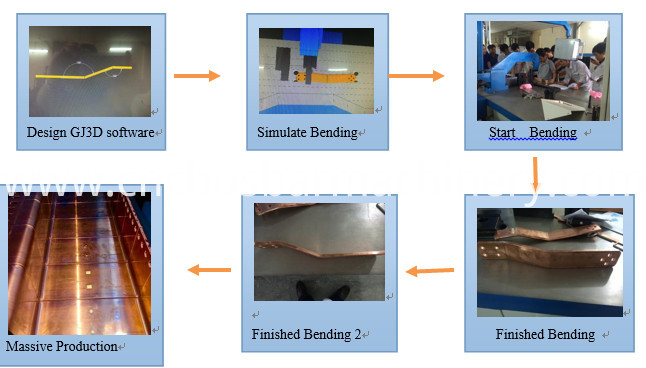

Core selling point: High-Accuracy

Applicable industry: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Where to provide local services (in which countries are there overseas service outlets): Viet Nam, Philippines

Showroom location (in which countries are there sample rooms overseas): Viet Nam, Philippines

Marketing type: Hot Product 2019

Mechanical test report: Provided

Video factory inspection: Provided

Core component warranty period: 1 Year

Core components: Motor, Pump, Plc, Engine, Other

Automation: Automatic

Suitable For: Aluminum

Condition: New

Type: Cnc Bending Machine