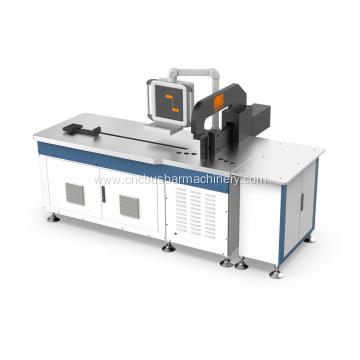

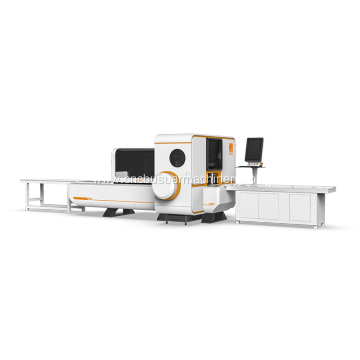

Model No.: HJ-400-4

Brand: YBBA

place of origin: China

Video factory inspection: Provided

Mechanical test report: Provided

Marketing type: Hot Product 2019

Core component warranty period: 1 Year

Core components: Motor

warranty period: 1 Year

status: New

Core selling point: Flexible Manufacturing

Out-of-warranty service: Video Technical Support, Online Support

Applicable industry: Manufacturing Plant

Where to provide local services (in which countries are there overseas service outlets): None

Showroom location (in which countries are there sample rooms overseas): None

Function: Abrasion Resistance

Certification: CE

Demoulding: Automatic

Condition: New

Warranty: 12 Months

Automatic Grade: Automatic

Installation: Desktop

Driven Type: Electric

Mould Life: >1,000,000 Shots

Installation Capacity: 35KW