Functional features:

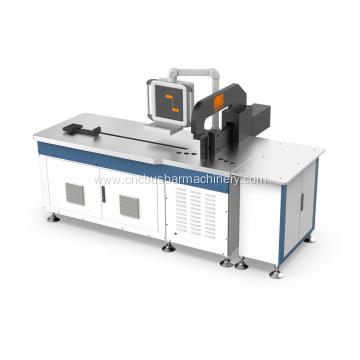

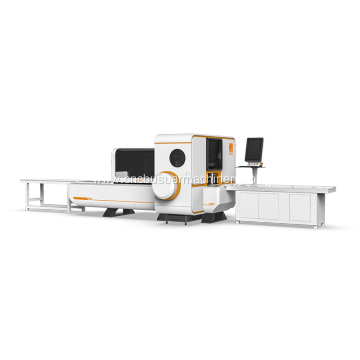

Cut To Length Line is specialized equipment for production of transformer cores. It consists of 2 shearing stations and 2 V-notching station to process the lamination of yoke, leg and center leg etc.

1. Cut To Length Line Machine can complete automatic production of various sheets for laminated, Full tapered seam cores.

2. Shearing power: the Cut To Length Machine imported electrical servo control technology is adopted, so the device is featured by high speed, low noise and long life.

3. Feeding power: cut to length line adopt high torque AC synchronous servo motor, so has characteristics such as rapid response, high positioning and accuracy, low noise, low braking thermal loss and long life.

4. Track positioning: for cut to length line the centralized positioning is achieved by dragging the linear tracks of the ball screw with a servo motor. So the positioning is rapid, accurate and convenient and the track width can be memorized automatically.

5. Movement control: advanced PCC control and ethernet powerlink communication technology is adopted, reducing greatly wiring and imporving the reliability, stability and real time of the system remote control and trouble diagnosis can be achieved via the above control and technology, shortening the maintenance time and reducing the cost to the largest extent.

Technical parameter

Type

Parameter | HJ-400-5 |

| Coil material width tolerance | ±0.1mm |

| Shearing burr | ≤0.02mm |

| S° deviation | Single direction ≤0.02mm/2000mm |

| Width of sheet | 40-440mm |

| Length of sheet | 350-2000mm (short side) |

| Thickness of sheet | 0.23-0.35mm |

| Accuracy in Length | ±0.2mm/2000mm |

| Shearing burr | ≤0.02mm |

| Lifetime of blade | Approx. Over 1.2 million cuts |

| Accuracy of shearing angle | ±0.025° |

| Max feeding speed | 0-240m/min |

| Cutting time per time | ≤0.023s (electrical) |

| Punching mold burr | ≤0.02mm |

| Lifetime of punching die | Approx. 0.3-0.5 million punches |

| Layers of step-lap | 1,2,3,4,5,6,7,8 |

| Max stacking thickness | 450mm (containing material board) |

| Human-machine interface | Touch screen soft keyboard |

| Size of whole machine (L*W*H) | 18m×8m×2.2m |

| Installation capacity | 25kw |

Packing pictures

Looking for ideal Transformer Lamination Price Manufacturer & supplier ? We have a wide selection at good prices to help you get creative. All the High Speed Core Cutting Line are quality guaranteed. We are China Origin Factory of Core Cutting Machine. If you have any question, please feel free to contact us.