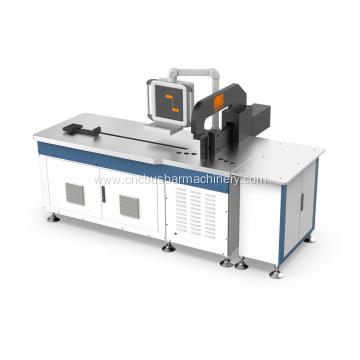

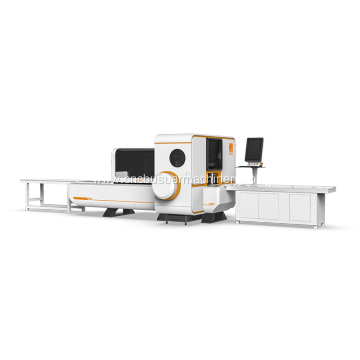

Model No.: HT-420

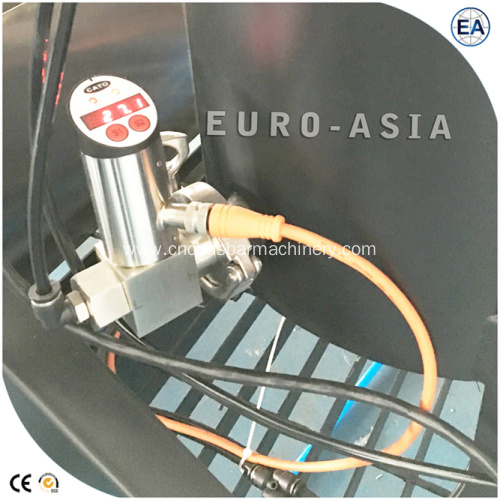

Brand: Ecoseal

Warranty Service: 1 Year

After-sales service: Online Technical Support, Onsite Installation, Onsite Training, Onsite Inspection, Free Spare Parts

Engineering solution capability: Graphic Design, 3d Model Design, Total Solution For Projects

Application scenario: Warehouse, Workshop, Bedroom, Storage & Closet

design style: European, Asian, Eclectic, Southwestern, Craftsman, Mid-Century Modern, Transitional, Tropical, Victorian, Japanese, Chinese, French

place of origin: China

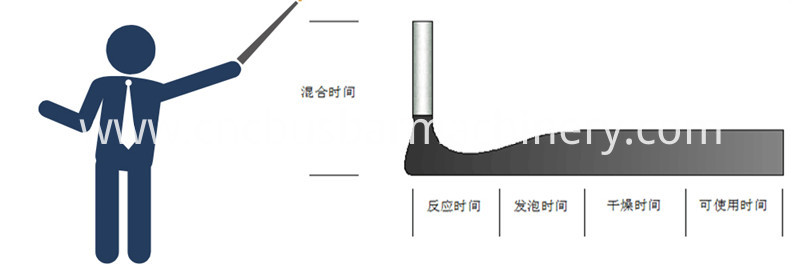

characteristic: Foam Soap Dispenser

main material: Metal

Types of soap dispenser: Automatic Soap Dispenser

Customized: Yes

Certification: CE

Precision: High Precision

Condition: New

Warranty: 12 Months

Automatic Grade: Automatic

Installation: Desktop

Driven Type: Electric